(I wasn’t willing to translate that myself; GPT-4 generated translation. German original here.)

Unhooking and Folding Away the Upper Casing Shell

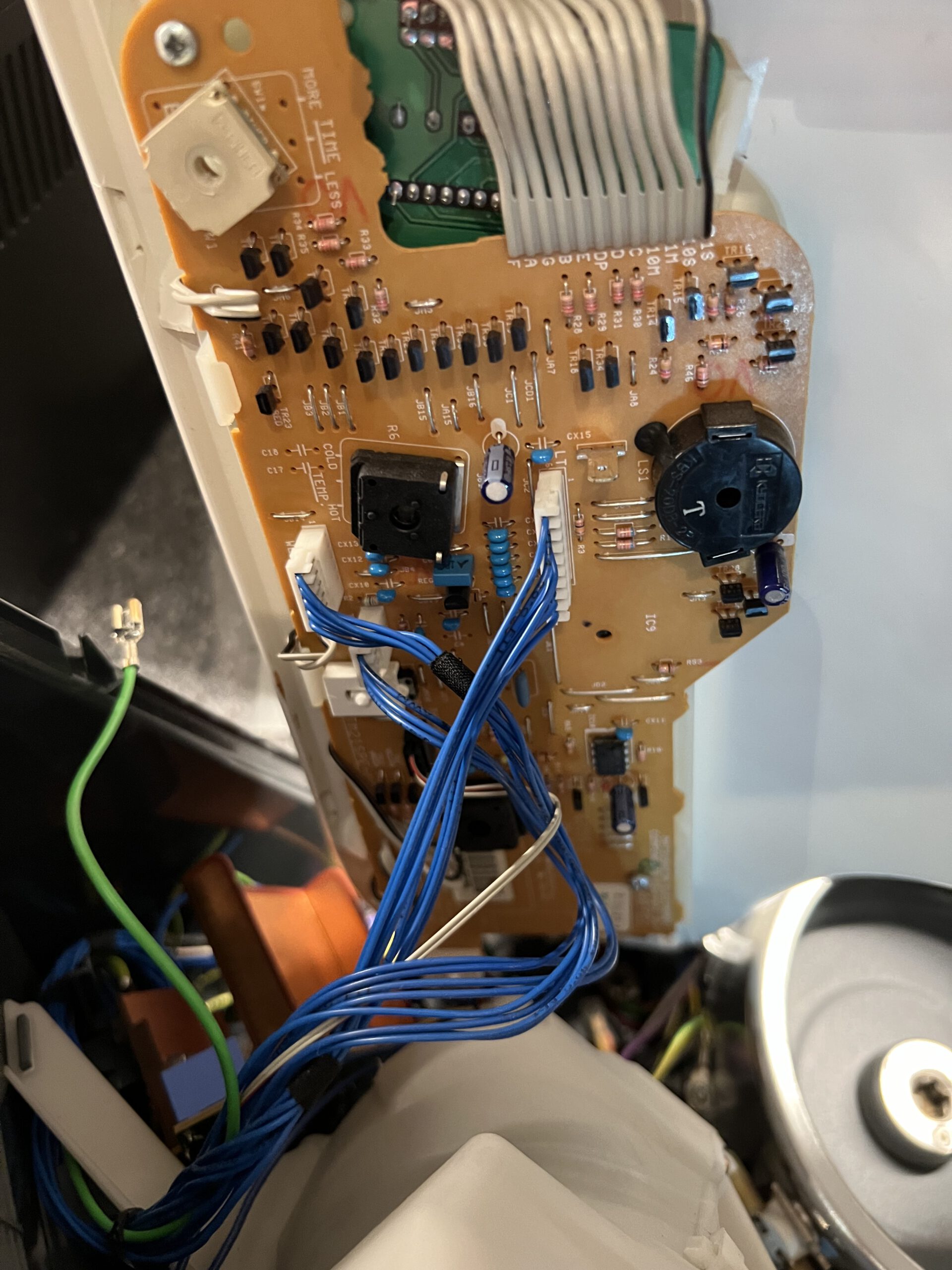

Next step is to unhook and fold away the upper casing shell. Disconnect the cables from the electronics – there are three white flat connectors with blue wires in different sizes, one black (with two grey cable cores), and the contact shoe of the green grounding wire. Once these are disconnected, you can remove the entire upper shell from the device.

Buggered those Push Buttons!

These can be tricky. That’s why it’s a good idea to watch a tutorial first.

Understanding the Push Buttons Mechanism

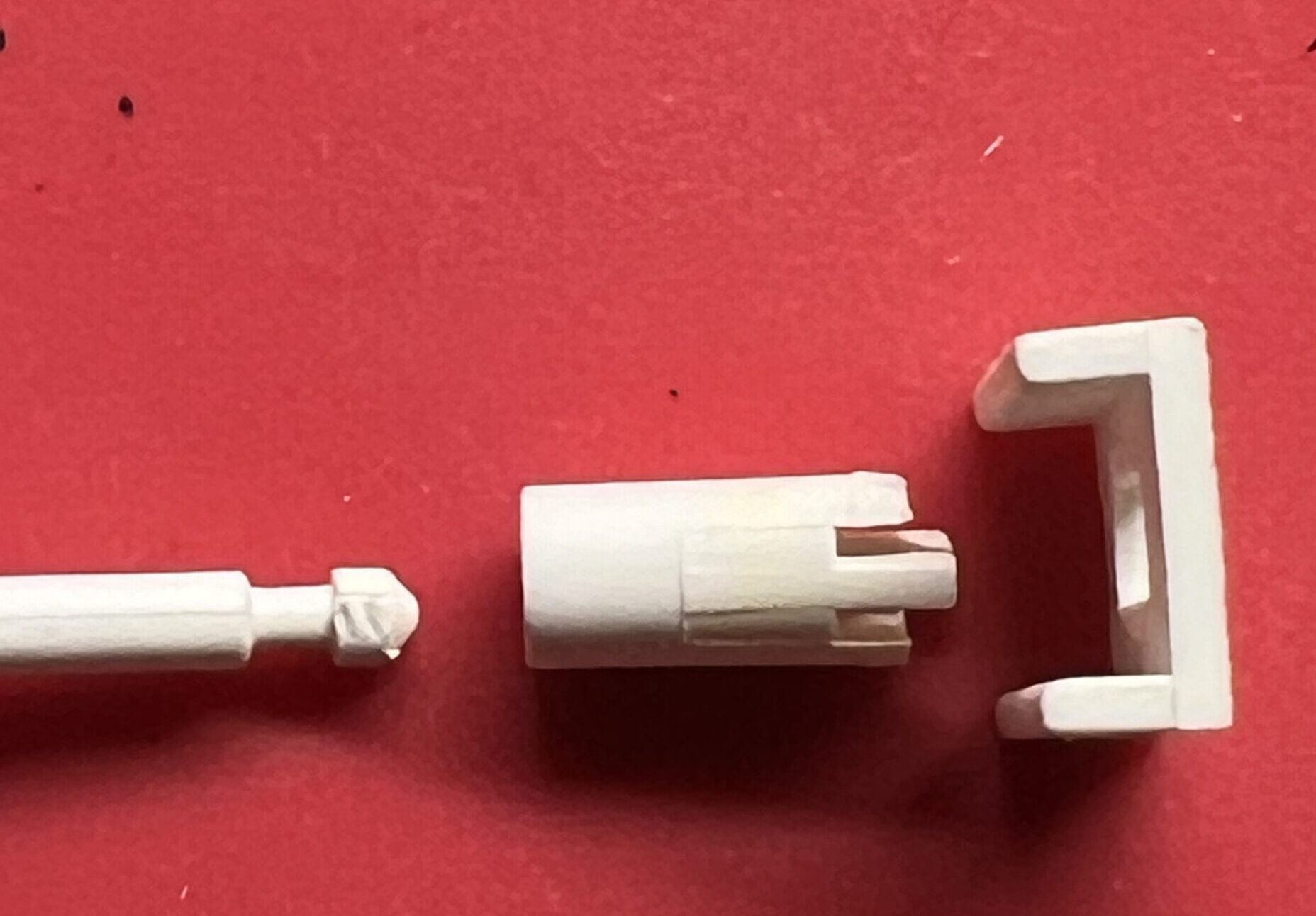

The push buttons are comprised of two main parts: the actual button, which protrudes from the front of the casing with a pin attached to it, and a counterpart that keeps the switch contact closed as long as no one presses the button. To remove the button, you need to detach the top part from the pin. That much is clear.

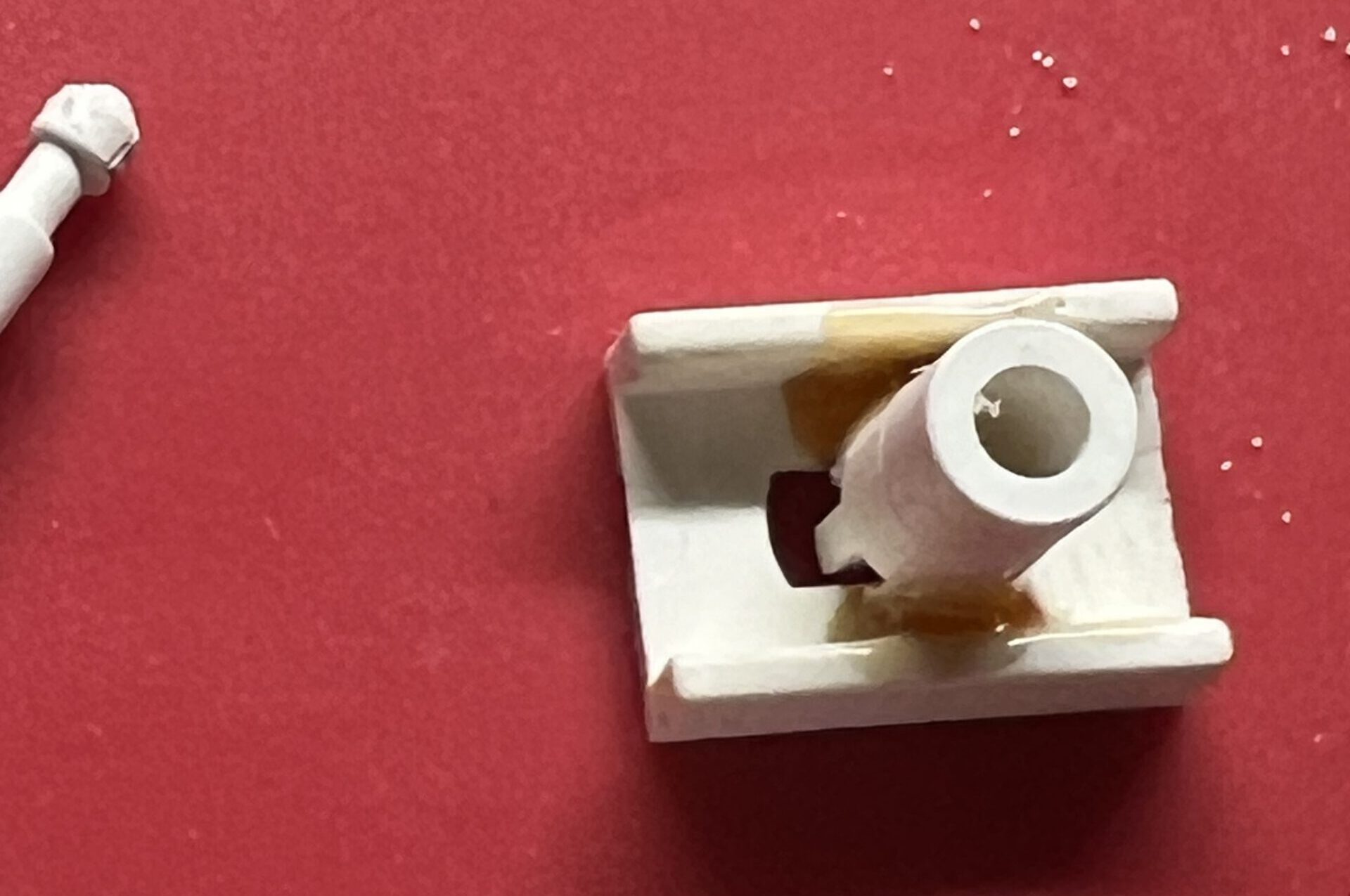

Unfortunately, the only solution I could think of was to use force, which led to me tearing off the rectangular plate on top. (This plate presses the switch.) It’s flanged to a tube where the pin goes, and at its upper end – visible through the slit below the plate – there are two small arms that hold the pin. You need to spread them apart using two small watchmaker’s screwdrivers, then you might be able to pull out the pin. Maybe.

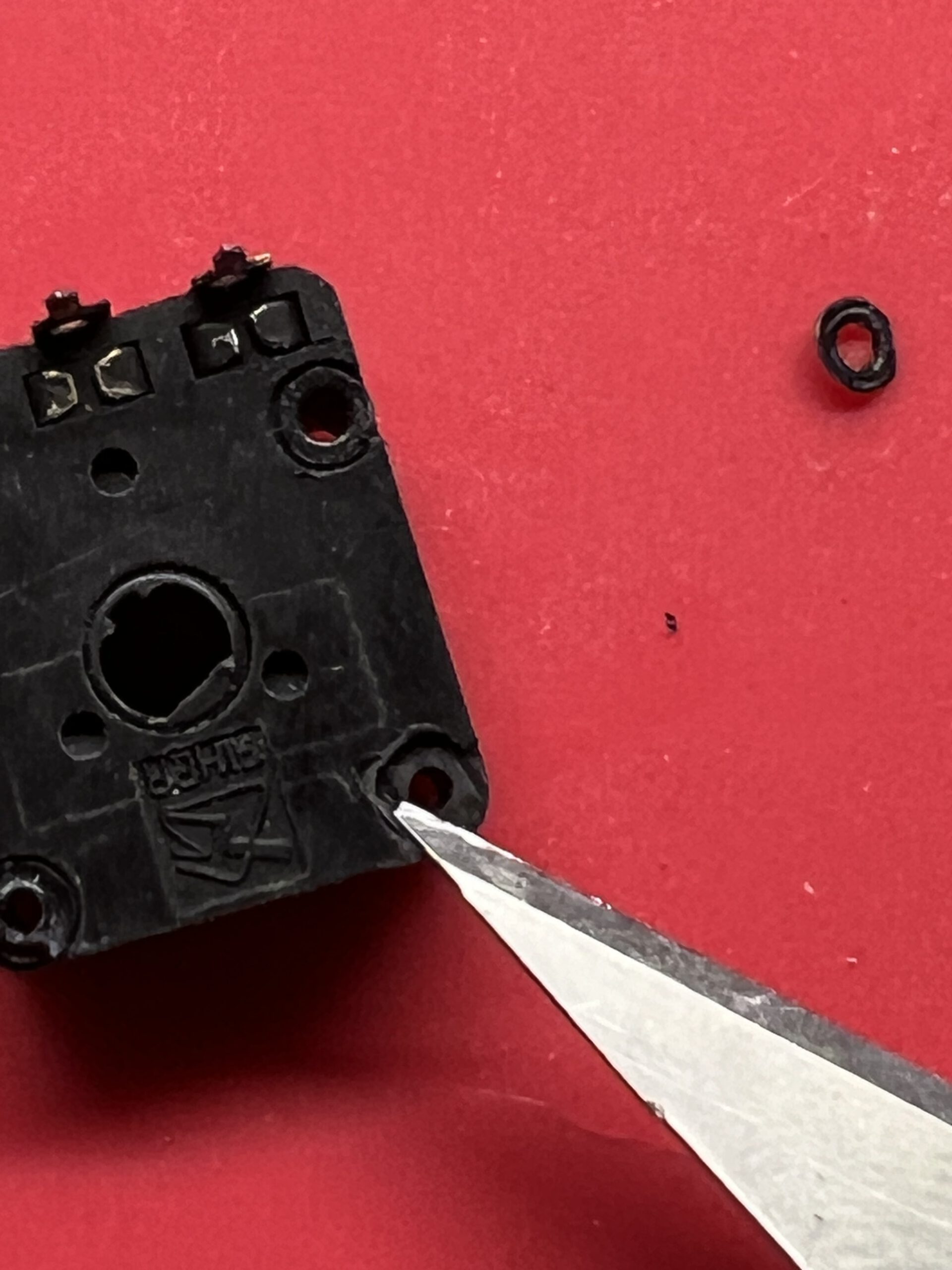

Or, it might end up looking like this – the part in the middle and the one on the right are actually supposed to be connected; I ended up brutally tearing them apart.

I resorted to the reliable two-component adhesive. It worked after reassembling, and I hope it holds permanently, though I’m not very confident. If I can’t find replacement parts, maybe I’ll 3D print them, or else I might just permanently attach the plate to the pin.

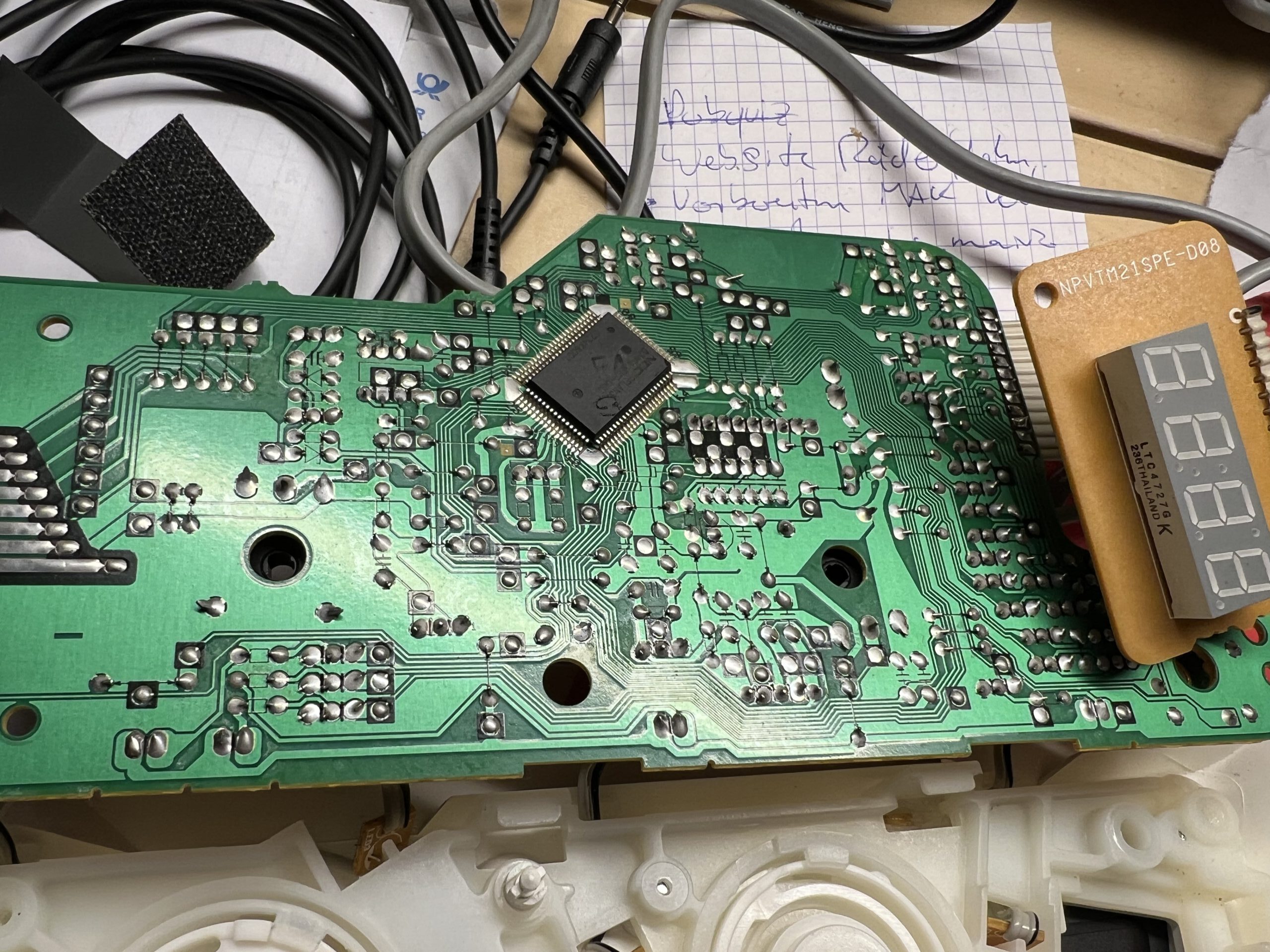

Next, unscrew the three screws from the circuit board and unhook the display, which is held in place by two plastic tabs. Then, remove the electronics.

The potentiometers are soldered at three contacts as usual and additionally held by two tabs that are inserted through the housing and bent over. Carefully unbend these, lift the three poles of the potentiometer, and remove it.

It’s a 22k potentiometer from Piher. I couldn’t find a replacement part quickly, so I decided to open it up. (Update: I’m trying with a Pipher PT15NH now; that’s the closest approximation I could find with that through-hole shaft. Piper datasheet here.)

The cover is pressed onto the housing from the bottom and riveted over four plastic pins; you have to cut these slightly with a scalpel, then the cover can be pried open.

With the potentiometer open, do what one does with open potentiometers – clean the wiper and track with isopropanol or mild alcohol, gently bend the wiper contacts back into shape, and – I am grinding my teeth while writing this – apply a little contact oil, if available. Absorb any excess oil, reassemble the potentiometer, solder it back in place, bend the tabs back, and it’s done.

Reassemble everything – and it works.

Verwandte Artikel:

- Fixing a Korg Polysix. A Polysix! (Saturday, 24. August 2024; Schlagworte: analog, Repair, Reparatur, Retro, Synthesizer, KLM-367, Korg Polysix)

- Sandwich toaster Krups FDK451 – how to dismount it to fix the holding clip (Saturday, 19. March 2022; Schlagworte: Reparatur, )

- Kaffeekampf: A Tale of Two Viennas (Sunday, 25. October 2009; Schlagworte: Demontage, Kaffeevollautomat, Reparatur, Saeco Vienna, Torx)

Vielen Dank für die Anleitung, hat mir sehr gut geholfen. ich hätte etwas kaputtgemacht ohne Deine Sehr gute Beschreibung.

Viele Grüße

Matthias

Danke, freut mich sehr!